Discovering the Benefits of Using Mass Containers in Modern Supply Chains

Making use of mass containers in modern-day supply chains presents a series of benefits that deserve careful factor to consider. These containers can result in substantial expense financial savings while improving logistical performance. They also play a vital function in minimizing packaging waste and enhancing storage space solutions. As markets progressively focus on sustainability, the prospective effect of bulk containers becomes a lot more relevant. What certain benefits can be realized by adopting this approach?

Price Savings With Mass Handling

Bulk handling provides significant price savings for organizations within contemporary supply chains. By making use of bulk containers, firms can lower product packaging expenses substantially, as fewer products are needed for transport and storage. This reduction in product packaging not only decreases costs but likewise minimizes waste, aligning with sustainability goals. In addition, mass handling enables more reliable transport, as bigger quantities can be delivered in less trips, leading to reduced freight expenses.

Labor costs likewise see a reduction; bulk materials normally require less hands-on handling, allowing team to focus on various other value-added tasks. The structured storage space of mass containers maximizes storehouse space, leading to prospective financial savings in functional or rental prices - used collapsible bulk containers. Overall, applying bulk handling techniques can significantly improve a company's bottom line, making it an eye-catching choice for organizations aiming to improve their price effectiveness in an open market

Improved Efficiency in Logistics

While standard supply chain methods frequently include fragmented procedures, the integration of mass containers significantly enhances logistics performance. These containers help with the streamlined activity of goods, lowering dealing with times and reducing the requirement for numerous transfers. By consolidating materials into less shipments, firms can maximize transport routes and minimize overall products prices.

The improved visibility offered by mass logistics allows real-time monitoring of deliveries, allowing supply chain supervisors to react swiftly to any disturbances. On the whole, the adoption of mass containers transforms logistics operations, cultivating an extra responsive and active supply chain that fulfills the needs of contemporary business.

Reduction of Product Packaging Waste

As companies look for to improve sustainability in their procedures, the use of mass containers plays a necessary role in lowering packaging waste. Typical packaging methods frequently include numerous layers, resulting in significant waste, both in materials and disposal. By using mass containers, businesses can notably lessen the amount of product packaging required, as these containers are made to be recycled and recycled. This change not just decreases the quantity of single-use packaging sent to land fills but additionally lowers the carbon impact related to manufacturing and moving product packaging products. Furthermore, bulk containers promote a lot more efficient loading processes, permitting a greater quantity of goods to be delivered at as soon as, thereby decreasing the need for excessive packaging. Eventually, embracing bulk containers results in an extra lasting supply chain, aligning operational exercise with environmental duty while likewise possibly lowering expenses linked with product packaging waste management.

Enhanced Storage Space Solutions

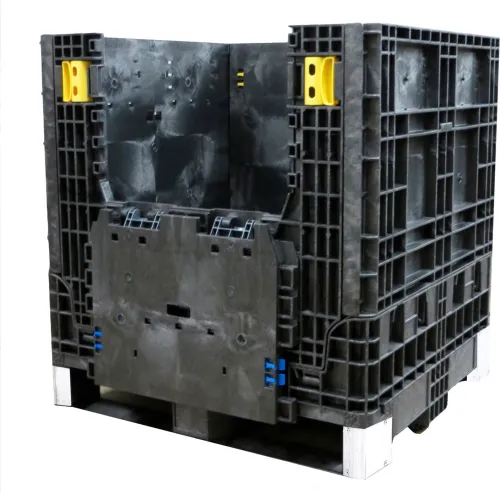

Efficient storage services are crucial for optimizing supply chain performance, specifically when mass containers are used. These containers take full advantage of area usage, enabling for higher density storage. Their consistent measurements enable stacking, which minimizes the footprint needed in click to find out more storage facilities and distribution centers. This organization not only boosts access yet likewise streamlines stock management.

In addition, bulk containers can be created to suit different materials, from fluids to solids, consequently using versatility in storage options. Their robust construction guarantees sturdiness, decreasing the risk of damages during handling and transportation. Services can experience less interruptions and reduced substitute expenses.

The standardization of mass containers facilitates easier combination into automated storage and access systems, additionally enhancing operational effectiveness. To conclude, the fostering of mass containers results additional resources in improved storage remedies that support streamlined procedures and contribute positively to general supply chain effectiveness.

Advertising Sustainability in Supply Chains

Promoting sustainability in supply chains has ended up being an essential focus for companies looking for to minimize their environmental effect. The fostering of bulk containers serves as an essential method for improving sustainability efforts. These containers, designed for reliable storage space and transport, considerably decrease packaging waste contrasted to conventional product packaging techniques. By using sturdy products, mass containers can be reused multiple times, even more reducing the demand for single-use product packaging.

Moreover, mass containers enhance logistics by making best use of space application throughout transport, therefore decreasing carbon exhausts connected with shipping. Services can also improve their supply chain processes, which contributes to reducing power intake. Furthermore, companies that prioritize sustainability often boost their brand online reputation, attracting eco mindful customers. Overall, integrating mass containers into supply chains not only advertises environmental responsibility yet additionally promotes operational efficiency, showing a complete approach to sustainable business techniques.

Often Asked Concerns

What Kinds of Products Are Finest Suited for Bulk Containers?

Products finest fit for bulk containers include grains, chemicals, fluids, and huge parts. These items gain from reliable storage space, transport, and lowered packaging waste, eventually boosting functional performance and cost-effectiveness within supply chain procedures.

Just How Do Mass Containers Impact Stock Management Practices?

Bulk containers enhance supply monitoring by decreasing dealing with times and optimizing storage space. They improve presence of stock levels, simplify monitoring, and promote even more accurate forecasting, inevitably useful site bring about improved performance and decreased operational prices.

Are There Details Industries That Advantage Most From Bulk Containers?

Specific sectors, such as agriculture, chemicals, and food processing, benefit most from bulk containers. used collapsible bulk containers. These industries use bulk containers to enhance efficiency, decrease expenses, and improve logistics, inevitably enhancing their supply chain procedures considerably

What Are the Safety Considerations When Utilizing Mass Containers?

Safety considerations when using mass containers consist of making sure architectural integrity, appropriate handling techniques, protected loading and dumping procedures, routine inspections for leaks or damage, and compliance with relevant laws to minimize risks throughout transportation and storage.

Exactly How Can Business Transition to Mass Container Equipments Effectively?

Firms can effectively move to bulk container systems by reviewing current logistics, educating team, gradually applying the new system, evaluating vendor capacities, and continually monitoring performance to assure efficiency and safety throughout the procedure. (used plastic containers)

The use of mass containers in contemporary supply chains provides an array of benefits that are worthy of mindful factor to consider. By using mass containers, companies can decrease product packaging prices considerably, as fewer materials are needed for transportation and storage space. While standard supply chain approaches typically involve fragmented processes, the integration of mass containers considerably boosts logistics performance. By using mass containers, services can especially decrease the amount of packaging needed, as these containers are made to be reused and reused. Efficient storage solutions are crucial for optimizing supply chain efficiency, specifically when mass containers are utilized.